Top Injection Mold Making Techniques in 2026 What to Know?

In the fast-evolving world of injection mold making, keeping up with cutting-edge techniques is crucial. Industry expert John Smith, a renowned leader in mold design, once stated, "Innovation is the lifeline for the future of injection mold making." His insight highlights the importance of adapting to new technology and methods.

As we approach 2026, several techniques are emerging. These advancements aim to improve efficiency and reduce costs. Innovations like 3D printing in mold fabrication are changing traditional practices. New materials are also being introduced, enhancing durability and precision. Yet, these changes come with challenges.

Not every company has the resources to adopt these advanced techniques. Smaller firms may struggle to keep pace. This raises questions about industry equality and accessibility. While 2026 promises exciting possibilities, the transition presents hurdles that the injection mold making sector must confront together. Understanding these dynamics will shape the future of mold manufacturing.

Overview of Injection Mold Making Techniques in 2026

In 2026, injection mold making techniques have advanced significantly. Modern methods focus on efficiency and precision. Data from recent industry reports show that over 70% of manufacturers are adopting advanced computer simulations. These techniques reduce production time and material waste. A significant trend is the move towards sustainable materials and practices. Emerging biodegradable polymers are expected to rise by 40% in usage.

The integration of automation has also transformed mold making. Robotic systems now handle tasks that were previously labor-intensive. This shift leads to faster production rates. However, companies often overlook the need for ongoing employee training. Even the best technology requires skilled operators. Many firms face challenges in bridging this skills gap.

**Tips:** Invest in staff training programs. This ensures your team is up to date with the latest technologies. Consider adopting hybrid techniques that combine traditional and modern processes. These methods can enhance quality while reducing costs. Regularly assess your techniques for areas of improvement. This reflection can lead to innovative solutions.

Advancements in Materials for Injection Mold Manufacturing

The landscape of injection mold manufacturing is shifting rapidly. In 2026, new materials are reshaping this industry.

Advanced composites and high-performance thermoplastics gain traction. These materials offer enhanced durability and flexibility.

They allow for lighter molds and faster cycles.

However, the transition to these advanced materials is not seamless. Many manufacturers face challenges in material compatibility.

Adjusting existing equipment can be costly and time-consuming. There is also the learning curve for workers.

Training sessions become essential to ensure efficient use.

Sustainability is another consideration. Biodegradable options are emerging, but they may not meet all performance standards.

Testing these materials is crucial before full-scale adoption. Adopting new technology always comes with risks.

Each step forward requires careful planning and reflection. Decisions must be strategic, considering both immediate needs and long-term effects.

Innovative Technologies Impacting Injection Mold Design

As we approach 2026, the landscape of injection mold design is evolving rapidly. Innovative technologies are redefining traditional practices. For instance, 3D printing is significantly shaping mold-making processes. According to a recent industry report, 30% of manufacturers are now using additive manufacturing for prototyping molds. This shift allows for faster iterations and complex geometries that were once impossible.

Another key innovation is the integration of advanced simulation software. This technology helps designers predict material behaviors and potential defects. Recent findings indicate that using simulation can reduce the prototyping stage by 40%. However, these tools come with challenges. Not all engineers are trained to use them effectively, leading to possible design flaws.

Additionally, automation is making its mark in mold production. Robotic systems are increasingly handling repetitive tasks, ensuring more consistency. Yet, over-reliance on automation can result in skill gaps among workers, highlighting a need for continuous training programs. Maintaining human oversight is crucial to address potential pitfalls in quality control. Balancing technology with skilled labor will be key as we move forward into this new era of injection mold making.

Top Injection Mold Making Techniques in 2026

This chart illustrates the popularity of various injection mold making techniques as projected for 2026. It highlights the increasing adoption of advanced technologies such as 3D printing, alongside traditional methods like injection molding and die casting.

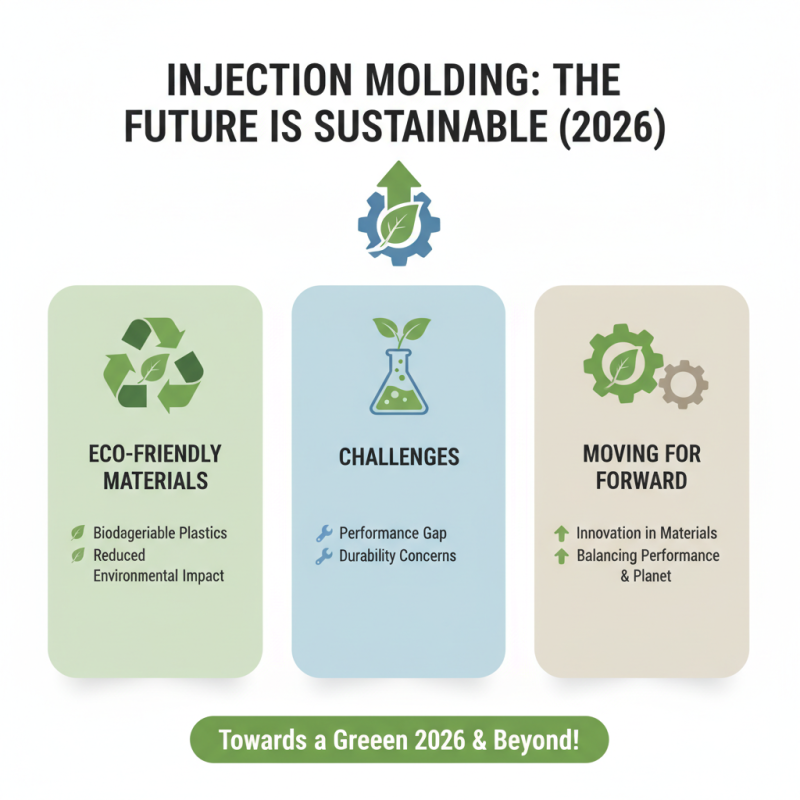

Sustainability Practices in Injection Mold Production

As we move towards 2026, sustainability in injection mold production becomes increasingly critical. Manufacturers are experimenting with eco-friendly materials. Biodegradable plastics are gaining traction. These materials can reduce environmental impact significantly. However, their performance often does not match conventional plastics. This presents a challenge for many manufacturers.

Energy efficiency also plays a vital role in sustainable practices. Modern injection molding machines now feature advanced energy-saving technologies. These innovations reduce energy consumption during production. But, many facilities still face hurdles in upgrading their machinery. Initial costs and unawareness can deter them from adopting these practices.

Furthermore, waste reduction is a key aspect. Techniques such as closed-loop recycling aim to minimize scrap generation. However, implementing such practices can be complex. Not all facilities have the resources or infrastructure to support this. Truly sustainable production requires a collective effort and constant reflection on current strategies.

Future Trends in Automation and Efficiency for Mold Making

The future of mold making is being shaped by advancements in automation and efficiency. By 2026, the injection mold industry expects a significant shift. Reports indicate a projected growth rate of 4.5% annually. Automation technologies, like AI and robotics, play a crucial role. These tools increase precision and reduce labor costs. However, many companies still grapple with implementation challenges.

Incorporating smart sensors is another emerging trend. These devices provide real-time data collection. They help in monitoring mold conditions and optimizing processes. While the initial investment may be high, the long-term benefits are undeniable. Some studies suggest that efficiency can improve by up to 30% with correct use of these tools. Yet, companies often overlook training for their workforce, which can hinder results.

Sustainability is also a key focus. Many industries are pushing for greener practices. The use of recycled materials in mold making is becoming more common. Innovations in biodegradable plastics further exemplify this trend. Despite these advancements, there’s resistance in some sectors. The gap between technology and tradition can create friction. Embracing change is essential, but not always easy. Adapting to new methods requires reflection and commitment.

Related Posts

-

The Future of Injection Mold Making Innovations Driving Efficiency and Cost Savings in Manufacturing

-

Top 10 Tips for Optimizing Injection Mold Manufacturing Efficiency

-

2025 Top 10 Trends in Injection Mold Making to Watch for Industry Growth and Innovation

-

2025 Top Trends in Injection Molding Prototyping You Need to Know

-

5 Digital Tips for Effective Injection Molding Prototyping Success

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023