How to Use Rapid Prototyping with Injection Molding for Fast Product Development

In today’s fast-paced product development landscape, the importance of efficient design and rapid innovation cannot be overstated. As companies strive to bring their ideas to market quicker than ever, techniques such as rapid prototyping injection molding have emerged as indispensable tools. According to Dr. Emily Carter, a leading expert in the field, “Rapid prototyping injection molding not only speeds up the manufacturing process but also enhances product design through iterative testing.” This statement underscores the dual benefits of this innovative approach, which allows designers to quickly create and test prototypes before committing to full-scale production.

The integration of rapid prototyping with injection molding streamlines the development cycle, enabling businesses to refine their concepts with greater agility and precision. By employing this methodology, teams can evaluate form, fit, and function early in the design process, reducing the risk of costly errors during later production stages. As organizations increasingly adopt these practices, they position themselves to respond dynamically to market demands, ultimately leading to a more competitive edge in their respective industries.

As we delve into the strategies and advantages of rapid prototyping injection molding, it is essential to recognize its transformative potential in expediting product development and fostering innovation. This exploration not only highlights the technical aspects of the process but also emphasizes its implications for creativity and efficiency in product design.

Understanding Rapid Prototyping: Definition and Applications

Rapid prototyping is a transformative approach in product development, characterized by quickly creating a scale model or prototype of a physical part using computer-aided design (CAD) software. This method allows engineers and designers to visualize, test, and refine ideas rapidly before committing to expensive manufacturing processes. By utilizing materials similar to those intended for final production, rapid prototyping not only helps in evaluating the form and fit but also serves as a vital tool in assessing functionality, all while minimizing time and costs.

The applications of rapid prototyping are vast, spanning across various industries such as automotive, aerospace, consumer goods, and medical devices. It enables teams to conduct rapid iterations based on user feedback or testing outcomes, significantly enhancing the design process. For instance, in the medical field, prototypes of surgical instruments can be produced and tested for ergonomics and usability, ensuring they meet user needs before moving into large-scale production. This iterative approach fosters innovation and significantly reduces the time-to-market for new products, making it an invaluable strategy in today’s fast-paced development environments.

How to Use Rapid Prototyping with Injection Molding for Fast Product Development

| Prototyping Method | Material Used | Production Speed | Cost Efficiency | Typical Applications |

|---|---|---|---|---|

| 3D Printing | PLA, ABS | 24-48 hours | High initial cost, low for small runs | Concept models, complex geometries |

| CNC Machining | Metal, Acrylic | 1-2 weeks | Moderate, cost-effective for medium runs | Functional prototypes, testing |

| Injection Molding | Silicone, Nylon | Several days to weeks | High initial setup, low per-part after | Mass production, consumer goods |

| Vacuum Casting | Polyurethane | 1-2 weeks | Cost-effective for small runs | Prototype testing, low-volume production |

| Hybrid Prototyping | Various composites | Variable, depending on method | Balanced for production and prototyping | Complex assemblies, rapid iterations |

Overview of Injection Molding Technology and Its Benefits

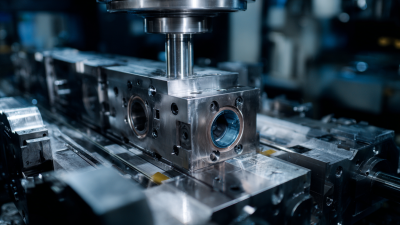

Injection molding is a widely used manufacturing process that enables the production of complex parts quickly and efficiently. This technology involves injecting molten material, typically thermoplastics or elastomers, into a pre-designed mold. Once the material cools and solidifies, the mold is opened to release the finished product. The precision and repeatability of injection molding make it an ideal choice for both low-volume prototypes and high-volume production runs.

One of the primary benefits of injection molding is its ability to create intricate designs with high dimensional accuracy. This allows for a greater level of detail compared to other manufacturing methods. Additionally, the speed at which components can be produced minimizes lead times, making it a preferred option for rapid prototyping. The efficiency of the process also results in lower material waste, further reducing production costs. With the capability of using various materials, companies can develop products that are lightweight, durable, and tailored to specific application needs, making injection molding a versatile solution for product development.

The Process of Creating Prototypes with Injection Molding

Rapid prototyping with injection molding has revolutionized product development, enabling companies to bring their ideas to market more efficiently than ever before. This process generally involves creating a mold for production that can produce prototypes quickly and with high precision. According to a 2021 report by Smithers, the global market for injection molding was valued at approximately $218 billion, with a notable segment focusing on rapid prototypes. This surge in demand underscores the importance of rapid prototyping not only for cost savings but also for accelerating the development timeline significantly.

The technique allows for the production of multiple prototypes in a short time frame, facilitating design iterations and testing. In fact, industry studies have shown that utilizing rapid prototyping methods can reduce development timelines by as much as 50%, thus enabling faster decision-making and reduced time to market. By creating physical models that mimic final products, companies can gather actionable feedback early in the development process. This iterative approach helps in fine-tuning product designs while simultaneously minimizing material waste and costs associated with traditional prototyping methods. As businesses continue to embrace innovation, the role of injection molding in rapid prototyping becomes increasingly vital, ensuring products meet both consumer expectations and market demands efficiently.

Integrating Rapid Prototyping into Product Development Workflow

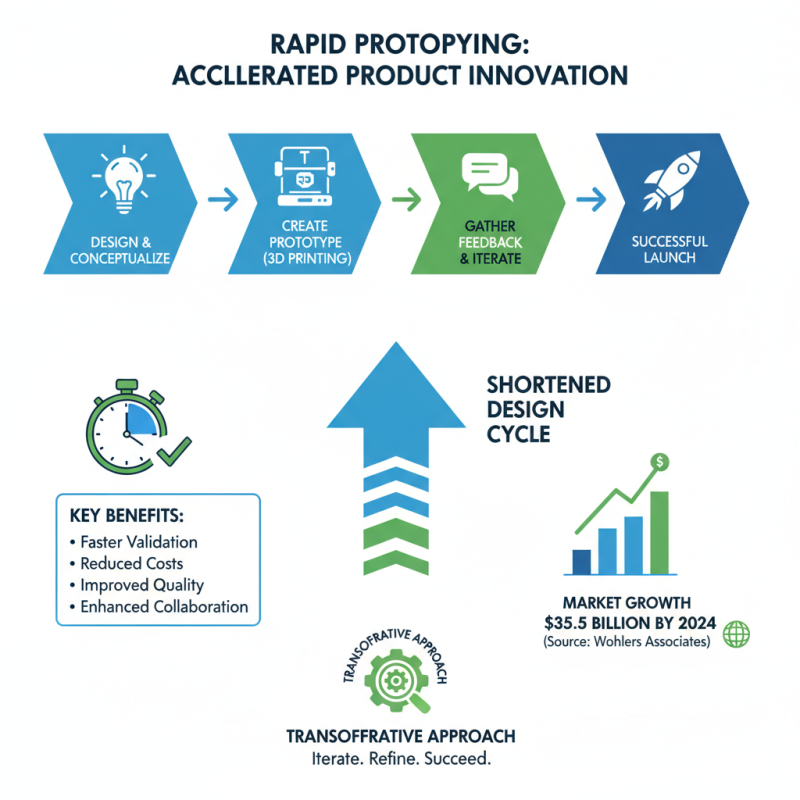

Integrating rapid prototyping into the product development workflow is a transformative approach that significantly shortens the design cycle and enhances product innovation. Rapid prototyping allows designers and engineers to create physical prototypes quickly using methods like 3D printing, ensuring that concepts are validated and refined early in the development process. According to a report by the Wohlers Associates, the market for additive manufacturing is expected to reach $35.5 billion by 2024, illustrating the growing reliance on rapid prototyping techniques across industries. This integration allows teams to iterate designs based on genuine feedback, ultimately leading to a more successful product launch.

One of the critical aspects of blending rapid prototyping with injection molding is the ability to produce and test components at an accelerated pace. By utilizing injection molding for high-volume production and rapid prototyping for design testing, businesses can reduce time-to-market by up to 75%, as reported by the consulting firm McKinsey. This synergy not only reduces costs associated with production revisions but also improves collaboration between designers and manufacturers, ensuring that the final products meet both consumer demands and market trends efficiently. Adopting this integrated workflow is essential for companies aiming to maintain a competitive edge in a fast-evolving marketplace.

Best Practices for Maximizing Efficiency in Prototype Production

Rapid prototyping with injection molding can significantly accelerate the product development process, allowing designers and engineers to quickly iterate on their ideas. To maximize efficiency in prototype production, adopting best practices is crucial. One effective approach is to streamline the design process. Simplifying designs can lead to faster mold creation and easier modifications, ultimately reducing production time.

Tips:

- Focus on creating a design that considers manufacturability from the outset.

- Utilize simulation software to identify potential issues in the design phase, thus reducing costly revisions later on.

Another key aspect is optimizing the flow of communication among team members. Regular check-ins and feedback loops can help align goals and expectations, enabling faster decision-making. Implementing a collaborative platform for sharing design files and updates can also enhance transparency and efficiency.

Tips:

- Schedule frequent design reviews to address any concerns early in the process.

- Encourage a culture of open communication where team members feel comfortable sharing ideas and challenges.

By integrating these practices, companies can leverage the advantages of rapid prototyping with injection molding to produce high-quality prototypes in a fraction of the time, paving the way for timely product launches.

Related Posts

-

Ultimate Guide to Achieving High Molding Precision in Manufacturing

-

How to Maximize Efficiency in Precision Injection Molding Processes

-

Understanding the Impact of Molding Precision on Sustainable Manufacturing Practices

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023

-

Exploring the Future of US Injection Molding: Innovations and Industry Trends

-

Contract Injection Molding Opportunities at 2025 China Import and Export Fair with Market Growth Projections