Best Practices for Rapid Prototyping Injection Molding in Product Development

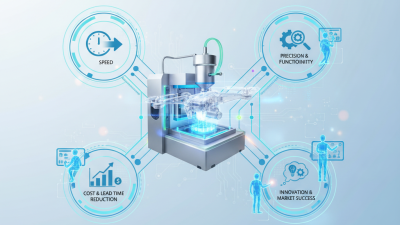

In the fast-paced world of product development, the ability to swiftly iterate and refine designs is paramount. Rapid prototyping injection molding has emerged as a key technique that significantly enhances the efficiency of this iterative process. By leveraging advanced technologies and materials, engineers and designers can create functional prototypes with remarkable speed and accuracy, enabling them to test concepts and make informed decisions earlier in the development cycle. This approach not only reduces time to market but also minimizes costs associated with traditional prototyping methods.

The integration of rapid prototyping injection molding into the product development workflow allows teams to visualize and assess their ideas with a tangible physical model. It supports comprehensive testing and optimization, thereby increasing the likelihood of a successful final product. Moreover, this method facilitates effective communication among stakeholders, ensuring that design specifications meet both functional and aesthetic requirements. As industries continue to evolve and demand for innovative solutions grows, adopting best practices in rapid prototyping injection molding will be crucial for maintaining a competitive edge in the market. In the following sections, we will explore the essential strategies and methodologies that can maximize the effectiveness of rapid prototyping injection molding in your product development efforts.

Best Practices for Rapid Prototyping Injection Molding in Product Development

In today's competitive landscape, rapid prototyping using injection molding has emerged as a pivotal component in product development. This approach allows companies to swiftly create prototypes, enabling faster iterations and more efficient design processes. According to a report by the Institute of Advanced Manufacturing, businesses employing rapid prototyping methodologies can reduce their product development time by up to 30%, leading to significant cost savings and market advantage.

Implementing best practices in rapid prototyping is essential to capitalize on these benefits. One key tip is to leverage computer-aided design (CAD) software to create precise 3D models, which can enhance the accuracy of injection molds. Additionally, integrating advanced simulation tools can predict how materials will behave during the molding process, further optimizing design and functionality, which is supported by data from the American Society for Quality.

Another crucial aspect is selecting the right materials for prototypes. While it may be tempting to use off-the-shelf options, investing in high-quality materials specifically suited for injection molding can lead to more reliable prototypes. Research from the Society of Plastics Engineers indicates that using optimized polymer blends can improve prototype durability and reduce revision cycles by up to 25%. Emphasizing these practices will not only streamline the product development process but also significantly enhance the end product's quality and reliability.

Understanding the Role of Rapid Prototyping in Injection Molding

Rapid prototyping plays a crucial role in the injection molding process, significantly enhancing product development efficiency. By allowing designers and engineers to create functional prototypes quickly, rapid prototyping helps in validating concepts and design features before entering mass production. This early-stage testing is essential for identifying potential design flaws and performance issues, which can be addressed in a timely manner, ultimately saving both time and costs associated with traditional production methods.

The integration of rapid prototyping in injection molding also fosters greater collaboration among cross-functional teams. By producing tangible prototypes, stakeholders can assess the product in real-world scenarios, providing valuable feedback that informs further design iterations. This collaborative approach not only aligns the product vision among team members but also accelerates decision-making processes. As technology continues to advance, the synergy between rapid prototyping and injection molding will likely lead to even more innovative practices in product development, enabling companies to meet market demands swiftly and effectively.

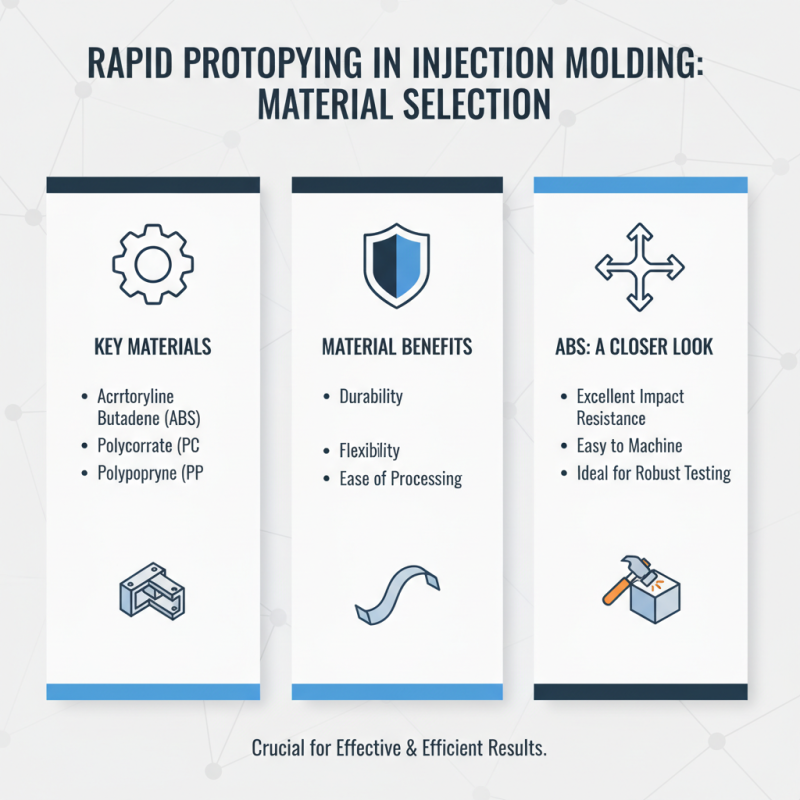

Key Materials for Effective Injection Molding Prototyping Techniques

When it comes to rapid prototyping in injection molding, selecting the right materials is crucial for achieving effective and efficient results. The choice of material can significantly influence not only the manufacturing process but also the performance characteristics of the prototype. Commonly used materials such as acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and polypropylene (PP) offer a blend of durability, flexibility, and ease of processing. ABS, for instance, is favored for its excellent impact resistance and ease of machining, making it ideal for prototypes that require robust testing.

Moreover, understanding the thermal properties and flow characteristics of each material is essential for optimizing the injection molding process. Using materials with suitable melting temperatures ensures that the prototyping process stays within the parameters that mitigate warping while still achieving detailed designs. Additionally, incorporating additives like glass fibers can enhance strength and rigidity, thus broadening the application scope of the prototypes. Ultimately, careful consideration of these materials and their properties allows for improved prototype fidelity and accelerates the product development cycle.

Common Challenges and Solutions in Rapid Prototyping for Injection Molding

Rapid prototyping in injection molding is a powerful tool in product development, yet it comes with its own set of challenges. One common issue is the material selection, as different applications may require specific physical or chemical properties that standard materials may not provide. Additionally, achieving the desired surface finish can be tricky, as initial prototypes may exhibit imperfections that need to be addressed before progressing to final production.

Tips: When selecting materials for rapid prototyping, it's essential to consider the end-use of the product. Conduct thorough testing to ensure the chosen material aligns with performance requirements.

Another challenge in rapid prototyping is managing the design for manufacturing (DFM) process. Complications can arise when prototype designs do not account for the limitations of the injection molding process, potentially leading to costly modifications later. Effective communication between design and manufacturing teams can mitigate this risk significantly.

Tips: Utilize software tools that allow for simulation of the molding process, which can help identify potential issues early in the design phase. Regularly review prototypes as they develop to ensure alignment with production capabilities.

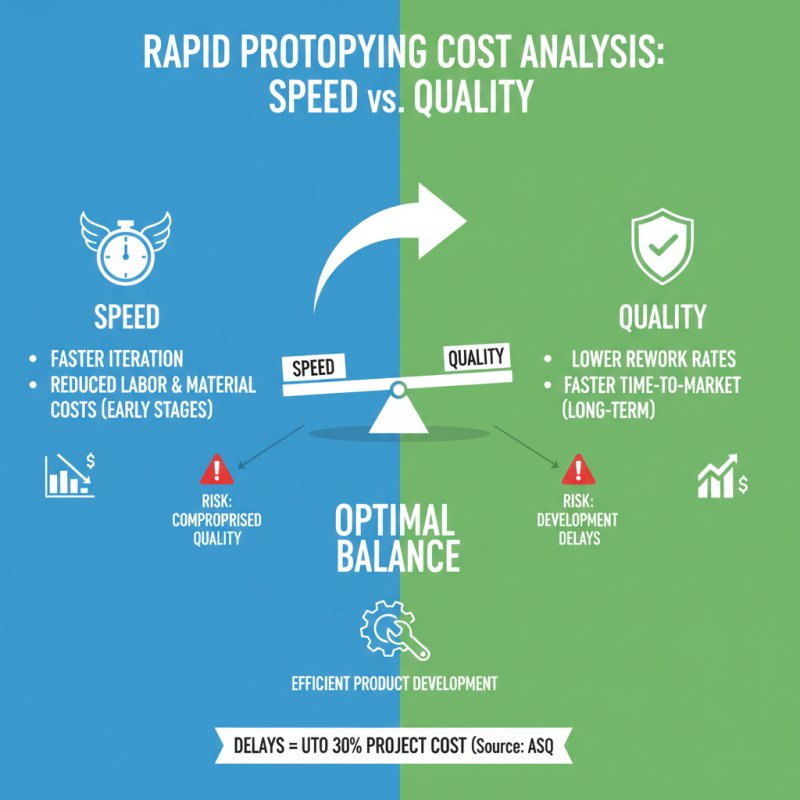

Cost Analysis: Balancing Speed and Quality in Prototyping Processes

Cost analysis in rapid prototyping using injection molding necessitates a delicate balance between speed and quality to ensure an efficient product development process. According to a report by the American Society for Quality, the cost of delays in product development can reach up to 30% of total project costs. Thus, adopting swift prototyping methods can lead to significant savings in labor and material costs, especially in the early stages of product design. However, rushed processes may compromise quality, potentially leading to higher rework rates and longer time-to-market.

In a study conducted by "IndustryQuest", it was found that companies that implement efficient prototyping practices can reduce their product development cycle time by 40% while maintaining quality standards. The analysis highlighted that investing in high-quality materials and sophisticated manufacturing techniques during the prototyping phase could reduce overall production costs by up to 20%. Companies are increasingly turning towards rapid injection molding with advanced simulation technologies, which allow for early identification of design flaws, thereby minimizing costly adjustments later in the production phase. By strategically investing in these rapid prototyping solutions, businesses can achieve a harmonious balance between speed and quality, facilitating a more streamlined and economically viable development process.

Conclusion

Rapid prototyping injection molding plays a crucial role in product development by allowing designers to quickly create and test prototypes before full-scale production. Understanding the techniques and best practices associated with this method helps in selecting the right materials and overcoming common challenges. Key materials, such as thermoplastics and silicone, are essential for effective prototyping and can significantly impact the performance of the final product.

Cost analysis becomes important in balancing speed and quality, ensuring that the rapid prototyping injection molding process remains efficient without sacrificing the integrity of the design. Real-world case studies demonstrate the successful applications of these practices, highlighting the benefits of rapid prototyping in reducing lead times and enhancing product innovation. By implementing these best practices, businesses can effectively streamline their development processes and respond quickly to market demands.

Related Posts

-

Top Benefits of Rapid Prototyping Injection Molding for Product Development

-

How to Leverage Rapid Prototyping Injection Molding for Faster Product Development

-

Tailored Solutions for Rapid Prototyping Injection Molding: Driving Efficiency with Accurate Data Insights

-

2025 Top Trends in Injection Molding Prototyping You Need to Know

-

Why Rapid Prototyping Injection Molding is Essential for Product Development

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency