Top Benefits of Rapid Prototyping Injection Molding for Product Development

In today's fast-paced product development landscape, the need for efficiency and speed has never been more crucial. Rapid prototyping injection molding has emerged as a transformative process that allows designers and engineers to create high-quality prototypes in a fraction of the time compared to traditional methods. According to industry expert Dr. Emily Chen, a leading figure in the field of additive manufacturing, “Rapid prototyping injection molding not only accelerates the design phase but also enhances the overall precision and functionality of the product.” This revolutionary approach has significantly streamlined the adjustments and iterations necessary for refining product designs, ensuring that teams can respond to market demands swiftly.

As the complexity of products continues to grow, maintaining the balance between innovation and manufacturability is a challenge that companies face. Rapid prototyping injection molding facilitates this balance by allowing stakeholders to visualize their ideas more concretely and identify potential issues early in the development cycle. By integrating this technology into their processes, organizations can reduce costs and lead times while improving product quality and customer satisfaction. Embracing rapid prototyping injection molding not only empowers teams to innovate but also positions them for success in an increasingly competitive marketplace.

Understanding Rapid Prototyping Injection Molding in Product Development

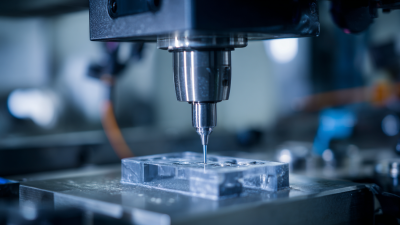

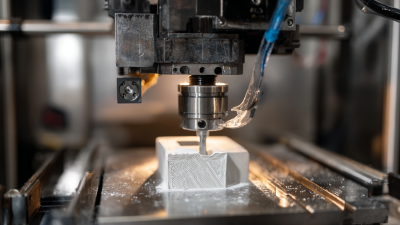

Rapid prototyping injection molding is a game-changer in the product development landscape, providing businesses with the agility to bring their ideas to life faster than traditional methods. This innovative approach allows designers and engineers to create high-quality prototypes in a shorter timeframe, enabling them to iterate and refine their products quickly. With the capability to test various materials and designs in real-world scenarios, teams can identify potential issues early in the development cycle, reducing costs and delays associated with later-stage modifications.

Tips for successful rapid prototyping include clearly defining your project requirements upfront to ensure that the prototypes meet your specifications. Moreover, consider collaborating closely with your manufacturing partners during the prototyping phase to streamline the transition from prototype to production. Utilizing advanced software for 3D modeling can enhance your design accuracy, making it easier to spot design flaws before they escalate into costly mistakes.

Emphasizing flexibility is also crucial in rapid prototyping. Be open to exploring different materials and manufacturing techniques as you develop your products. This flexibility not only fosters innovation but also allows you to make informed decisions that align with market needs and consumer preferences. By embracing this iterative process, businesses can stay ahead of the competition and successfully launch products that resonate with their target audience.

Top Benefits of Rapid Prototyping Injection Molding for Product Development

| Benefit | Description | Impact on Development | Example Applications |

|---|---|---|---|

| Speed | Rapid prototyping allows for quicker turnaround times in product development. | Faster time-to-market, enabling quicker feedback and adjustments. | Consumer electronics, automotive parts. |

| Cost Efficiency | Reduces costs associated with traditional tooling and manufacturing. | Lower initial investment, allowing testing before full-scale production. | Prototyping for medical devices, consumer goods. |

| Design Flexibility | Easily modify designs based on testing and feedback. | Encourages innovation and iterative development processes. | Aerospace components, custom tooling. |

| Material Variety | Support for various materials to simulate final products. | Improved accuracy in performance testing and validation. | Packaging designs, industrial components. |

| Collaboration | Facilitates better communication among teams through tangible prototypes. | Enhances teamwork and alignment on project goals. | Product design teams in various industries. |

Key Advantages of Using Rapid Prototyping for Initial Design Testing

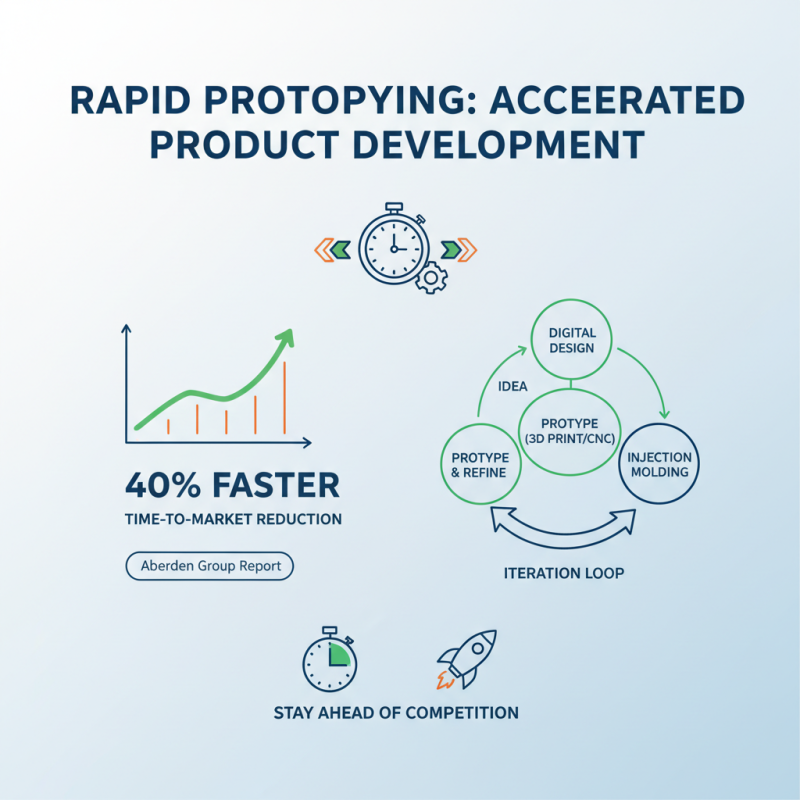

Rapid prototyping has emerged as a game-changer in the field of product development, particularly when it comes to injection molding. One of the key advantages of utilizing rapid prototyping for initial design testing is its ability to significantly reduce time-to-market. According to a report by the Aberdeen Group, companies that implement rapid prototyping can accelerate their product development cycles by up to 40%. This reduction in timeline allows businesses to respond more swiftly to market demands, ensuring that they stay ahead of their competitors.

Moreover, rapid prototyping provides valuable insights into design flaws early in the product development process. By creating functional prototypes, designers can conduct thorough testing and validation. A survey conducted by the Product Development and Management Association (PDMA) found that organizations that utilize prototyping in their design phase are 30% more likely to identify potential issues before mass production. This proactive approach not only saves costs associated with post-production modifications but also enhances overall product quality and user satisfaction, ultimately leading to a more successful product launch.

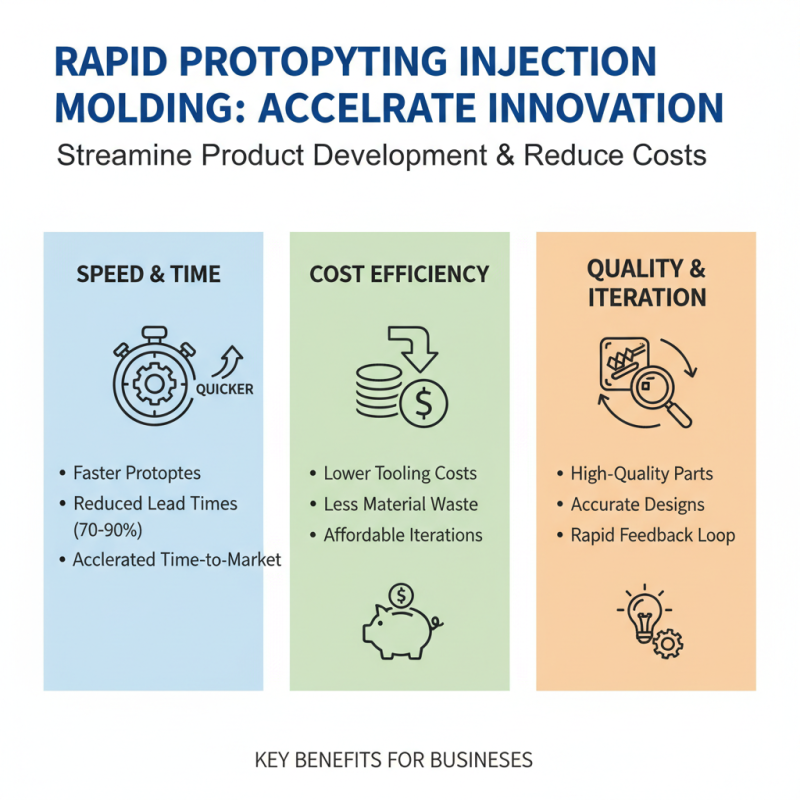

Cost-Effectiveness of Rapid Prototyping Injection Molding for Businesses

Rapid prototyping injection molding has emerged as a game-changer for businesses looking to streamline their product development processes while keeping costs manageable. One of the primary advantages of this technique is its ability to produce high-quality prototypes in a fraction of the time compared to traditional methods. By utilizing advanced technologies, companies can create accurate molds from digital designs, significantly reducing lead times. This not only accelerates the time to market but also allows for quicker iterations based on user feedback, which is essential in today’s fast-paced competitive landscape.

Moreover, the cost-effectiveness of rapid prototyping injection molding cannot be overstated. By minimizing material waste and reducing the need for extensive tooling, businesses can save substantial amounts of money during the early stages of product development. The ability to make changes to prototypes without incurring prohibitive costs makes this method particularly appealing for startups and small enterprises. Additionally, the scalability of this process means that companies can easily adjust production volumes based on market demand, further optimizing financial resources. In essence, rapid prototyping injection molding serves as a strategic investment, enabling companies to innovate while maintaining fiscal responsibility.

Accelerating Time-to-Market with Rapid Prototyping Techniques

Rapid prototyping injection molding has revolutionized the product development landscape, significantly reducing the time it takes to bring new products to market. By enabling designers and engineers to create high-fidelity prototypes quickly, teams can test and refine their ideas in a fraction of the traditional development time. This accelerated process not only enhances collaboration across departments but also allows for faster feedback loops, ensuring that any necessary adjustments can be made early in the development cycle.

In an increasingly competitive market, speed is essential. Companies that leverage rapid prototyping techniques can effectively shorten their development timelines, allowing them to respond swiftly to consumer needs and trends. This agility not only fosters innovation but also enables businesses to seize market opportunities faster than their competitors. By streamlining the product development process, organizations can confidently launch products that meet the demands of their target audience, ultimately driving growth and profitability in today's fast-paced environment.

Top Benefits of Rapid Prototyping Injection Molding for Product Development

This chart illustrates the key benefits of utilizing rapid prototyping injection molding in product development, highlighting how it accelerates time-to-market.

Enhancing Product Quality Through Iterative Prototyping Processes

Rapid prototyping injection molding has emerged as a transformative approach in product development, particularly in enhancing product quality. By utilizing iterative prototyping processes, designers can quickly create multiple iterations of a product, allowing for better testing and evaluation before final production. This methodology not only shortens the development cycle but also ensures that any potential flaws are identified and addressed early on. As a result, the fidelity of the final product is significantly improved, meeting both functionality and aesthetic requirements.

Tips for successfully leveraging rapid prototyping injection molding include focusing on clear specifications from the outset. Ensure that every design team member understands the goals and constraints of the project. Additionally, embrace feedback loops; gather insights from testing phases and make necessary adjustments promptly. Lastly, maintain open communication throughout the process, which is essential for integrating different perspectives and enhancing the overall quality of the end product. By following these tips, companies can harness the full potential of rapid prototyping to achieve superior product quality and efficiency.

Related Posts

-

How to Leverage Rapid Prototyping Injection Molding for Faster Product Development

-

How to Effectively Utilize Injection Molding Prototyping for Your Product Development

-

Tailored Solutions for Rapid Prototyping Injection Molding: Driving Efficiency with Accurate Data Insights

-

How to Optimize Insert Injection Molding for Increased Efficiency

-

Why Rapid Prototyping Injection Molding is Essential for Product Development

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency