What is Precision Molding and How Does it Impact Manufacturing Efficiency

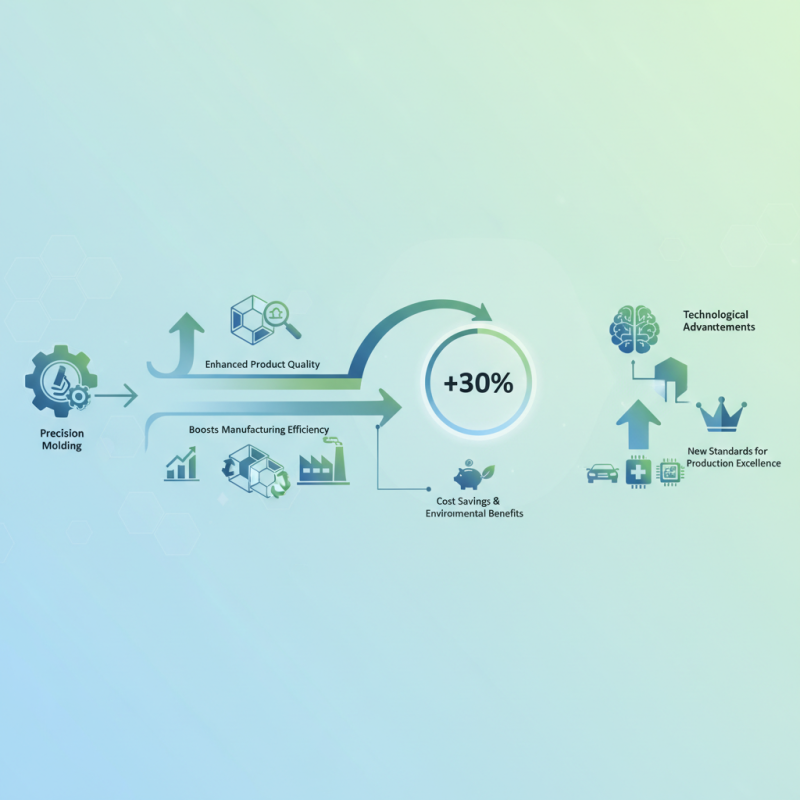

In today’s fast-paced manufacturing landscape, the importance of precision molding has become increasingly apparent. This advanced technique not only enhances product quality but also significantly boosts manufacturing efficiency. According to a recent report by the International Society of Precision Molding (ISPM), companies that adopt precision molding technologies have reported a staggering increase in production efficiency by up to 30%. This remarkable improvement stems from the ability of precision molding to produce intricate designs with minimal material waste, leading to both cost savings and environmental benefits.

Experts in the field, such as Dr. Emily Grant, a leading authority on precision molding, emphasize its transformative impact on manufacturing processes. Dr. Grant states, “Precision molding is not just a technique; it’s a paradigm shift that enables manufacturers to achieve higher accuracy and lower operational costs without compromising quality.” As industries increasingly prioritize sustainability and efficiency, the role of precision molding will undoubtedly continue to grow, setting new standards for production excellence.

As we delve deeper into the intricacies of precision molding, we will explore its applications across various sectors, the technological advancements that have propelled its adoption, and the key factors that contribute to enhanced manufacturing efficiency. This examination will illuminate how precision molding is redefining the future of manufacturing.

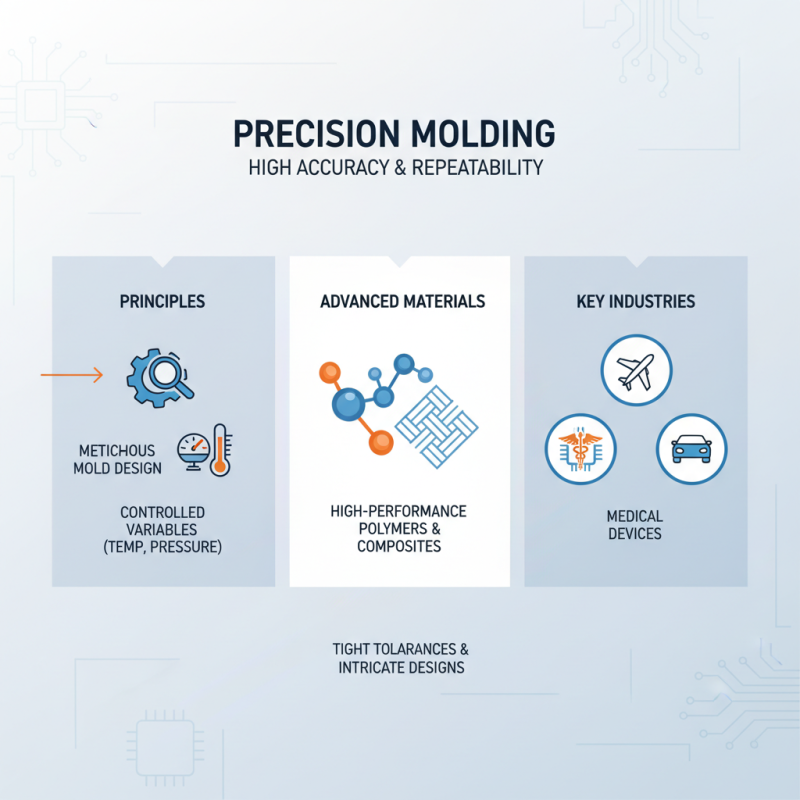

Understanding Precision Molding: Definition and Principles

Precision molding is a manufacturing process characterized by its ability to produce parts with high dimensional accuracy and repeatability. The principles of precision molding rely on the meticulous design of molds and the careful control of processing variables such as temperature, pressure, and material properties. This method typically utilizes advanced materials, including high-performance polymers and composites, allowing it to cater to industries requiring tight tolerances and intricate designs, such as aerospace, medical devices, and automotive manufacturing.

According to a report from the Plastic Industry Association, precision molding can improve manufacturing efficiency by up to 30% compared to traditional molding techniques. The enhanced reproducibility decreases the amount of material waste and reduces production time due to fewer defects and reworks. Industry data indicates that the global precision molding market is projected to grow significantly, reflecting an increasing demand for quality and performance in manufacturing processes. By incorporating state-of-the-art machinery and simulation technologies, manufacturers can optimize their workflows, leading to increased output and cost reductions, thereby positively impacting overall productivity in the sector.

The Role of Precision Molding in Modern Manufacturing Processes

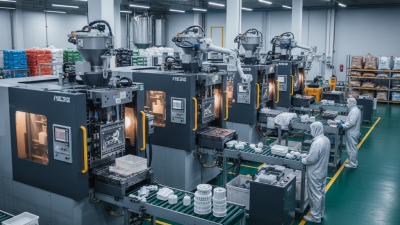

Precision molding has become an essential component in modern manufacturing processes, enhancing efficiency and accuracy across various industries. This technique ensures that components are produced with meticulous attention to detail, resulting in higher-quality products while minimizing waste. By utilizing advanced machinery and materials, precision molding allows for consistent reproduction of intricate designs, which is critical in sectors such as automotive, aerospace, and consumer electronics.

One notable advantage of precision molding is its ability to streamline production timelines. Manufacturers can achieve faster turnaround times as the molds are designed for optimal performance, allowing for rapid prototyping and mass production. This not only increases throughput but also reduces costs associated with rework and defects. The precision of the molds also leads to a significant reduction in material waste, aligning manufacturing practices with sustainability goals.

Tips: To maximize the benefits of precision molding, consider investing in high-quality tooling and regularly maintaining your equipment to ensure optimal performance. Additionally, integrating smart manufacturing technologies, such as IoT devices, can enhance process monitoring and control, leading to improved production metrics and efficiency. Understanding the specific requirements of your projects and selecting the right materials can further bolster the advantages offered by precision molding.

Benefits of Precision Molding on Production Efficiency and Cost Reduction

Precision molding is a manufacturing process that enhances production efficiency by creating high-accuracy and complex components. According to a report by the Society of Plastics Engineers, precision molding can reduce cycle times by up to 30% when compared to traditional molding techniques. This efficiency is achieved through advanced technologies that allow for more precise temperature and pressure control, enabling faster production without compromising the quality of the final product.

One of the key benefits of precision molding is its significant impact on cost reduction. A study published in the Journal of Manufacturing Science and Engineering found that companies utilizing precision molding experienced a reduction in scrap rates by as much as 50%. This decrease not only streamlines operations but also leads to lower material costs, ultimately contributing to an improved bottom line.

Furthermore, as precision molding reduces the need for extensive finishing processes, manufacturers can allocate resources more effectively and improve overall productivity. By minimizing waste and maximizing efficiency, precision molding serves as a crucial component in modern manufacturing strategies.

Applications of Precision Molding Across Various Industries

Precision molding is increasingly popular across various industries due to its ability to produce highly detailed and accurate components. In the automotive sector, precision molding is utilized to create intricate parts, such as dashboards and brackets, which require exact specifications to ensure safety and performance. The ability to replicate complex shapes with minimal waste enhances efficiency while reducing production costs. Similarly, the electronics industry benefits from precision molding by producing casings and connectors that must adhere to extremely tight tolerances.

In the medical field, precision molding plays a crucial role in the creation of components used in devices like syringes and implants. The importance of precision cannot be overstated, as even a minor error in manufacturing can lead to significant consequences for patient safety. Additionally, the consumer goods market has embraced precision molding for producing items such as household products and toys, where consistency and safety are key.

Tip: When considering precision molding for your next project, assess the complexity of the design and the materials to be used. This will help in determining the most suitable molding technique to enhance production efficiency. Moreover, collaborating with experienced engineers can ensure that the molds are designed for optimal performance, thus preventing costly delays during the production phase.

Impact of Precision Molding on Manufacturing Efficiency

Future Trends in Precision Molding Technology and Its Impact on Manufacturing

The precision molding industry is witnessing remarkable advancements that significantly enhance manufacturing efficiency. According to a recent report from Markets and Markets, the global precision molding market is projected to grow from $4.5 billion in 2022 to over $6.8 billion by 2027, at a compound annual growth rate (CAGR) of 8.5%. This growth is primarily driven by the increasing demand for high-precision components in industries such as automotive, medical, and electronics. With the integration of innovative materials and smart technologies, precision molding is set to streamline production processes, reduce waste, and improve product quality.

Emerging technologies such as 3D printing, automation, and smart sensors are at the forefront of transforming precision molding practices. A study by Deloitte indicates that the adoption of Industry 4.0 technologies can improve operational efficiency by up to 30%. These advancements allow for greater customization, faster production times, and more sustainable manufacturing practices. Additionally, as the demand for lightweight and complex designs increases, precision molding techniques are evolving to meet these challenges, offering manufacturers enhanced flexibility and capability to innovate. The convergence of technology and molding processes signifies a future where manufacturing is not just quicker but also more adaptable to changing market needs.

Related Posts

-

Ultimate Guide to Precision Injection Molding for Global Buyers in 2023

-

10 Best Injection Molding Techniques for Maximizing Efficiency in Production

-

2025 Top Trends in Injection Molding Prototyping You Need to Know

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023

-

Innovative Solutions for Rapid Injection Molding Efficiency Optimization