What is Precision Molding and Its Applications in Industry?

Precision molding is a pivotal process in modern manufacturing. It enables the consistent production of high-quality parts used across various industries. As John Smith, a renowned expert in precision molding, once said, "Precision molding is not just about accuracy; it's about creating possibilities for innovation." This technique contributes to sectors such as automotive, aerospace, and medical devices, where tight tolerances are critical.

Every day, industries rely on precision molding to enhance their products. For instance, in automotive manufacturing, components must fit perfectly for optimal performance. Yet, achieving such accuracy can pose challenges. Variabilities in materials and processes might lead to defects. It's crucial for engineers to continually assess and refine their methods. The balance between cost-efficiency and quality remains a complex issue in the field.

Despite advancements, not every molded part meets the desired specifications. Companies must invest in training and technology to improve outcomes. While precision molding holds tremendous potential, it also demands constant reflection and adaptation. This ongoing journey shapes how industries evolve and respond to consumer needs while emphasizing the essence of precision molding in their operations.

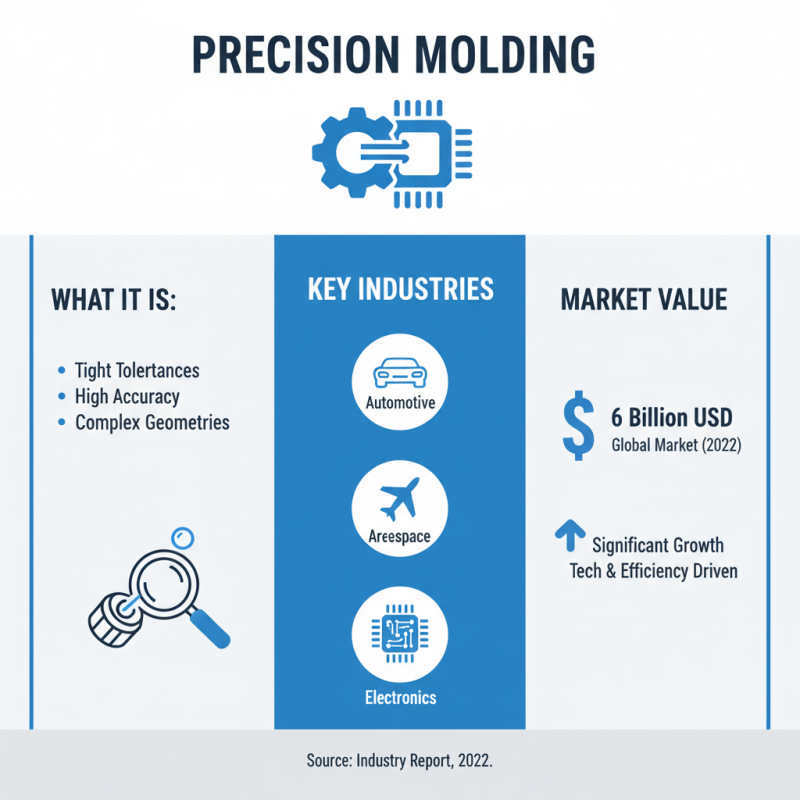

Definition of Precision Molding in Manufacturing Processes

Precision molding is a manufacturing process that focuses on creating parts with tight tolerances and high accuracy. This method is critical in industries like automotive, aerospace, and electronics. According to a recent industry report, the global precision molding market was valued at approximately $6 billion in 2022, indicating a strong demand for high-quality components. This sector anticipates significant growth, fueled by technological advancements and the push for efficiency.

In precision molding, the materials used play a vital role. Engineers often opt for materials such as thermoplastics and metals, which offer both durability and fine detail. The process demands a keen eye for detail and accuracy in every stage. However, achieving perfect results can be challenging. Even experienced professionals may encounter defects during mold creation. A study found that up to 15% of molded parts fail quality control tests. This necessitates a constant review of processes and materials used to improve outcomes and refine techniques. Continuous innovation remains essential to address these challenges.

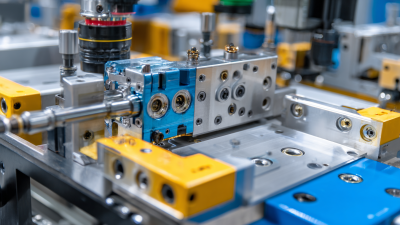

Key Techniques Used in Precision Molding

Precision molding is a critical process in modern manufacturing, allowing for the production of intricate parts with high accuracy. Key techniques in precision molding include injection molding, compression molding, and blow molding. According to a recent industry report, the global injection molding market is expected to reach $367 billion by 2027, showcasing its significance.

Injection molding uses molten materials to create precise shapes. This process can produce complex geometries and tight tolerances, essential for industries like automotive and electronics. Compression molding, on the other hand, involves placing a material into a heated mold. While this technique can be energy-efficient, it may not achieve the same precision as injection molding. Additionally, blow molding is particularly suited for hollow parts, a method widely used in packaging. However, each technique has its limitations and may require strict quality control measures.

Despite its benefits, precision molding is not without challenges. Variability in raw materials can affect the final product's quality. Environmental factors like temperature and humidity play significant roles in production. Manufacturers must continually evaluate their processes and adapt to these variables. Identifying areas for improvement can lead to better outcomes and efficiency in the long run.

What is Precision Molding and Its Applications in Industry? - Key Techniques Used in Precision Molding

| Technique | Application | Material Used | Advantages |

|---|---|---|---|

| Injection Molding | Consumer Goods, Automotive Parts | Plastics (e.g., ABS, Polycarbonate) | High Efficiency, Low Cost for Mass Production |

| Blow Molding | Packaging, Containers | Polyethylene, PET | Lightweight, Good Strength |

| Compression Molding | Electrical Components, Rubber Products | Rubber, Thermosetting Plastics | Good Surface Finish, Large Parts Available |

| Thermoforming | Food Packaging, Medical Supplies | PVC, PETG, Polypropylene | Flexibility, Quick Turnaround |

| Rotational Molding | Large Hollow Objects, Storage Tanks | Polyethylene, Nylon | Uniform Thickness, Lightweight Products |

Advantages of Precision Molding Over Traditional Methods

Precision molding offers numerous advantages over traditional methods. The technology enhances the accuracy and repeatability of the molding process. This is crucial when producing complex parts with tight tolerances. With precision molding, manufacturers can achieve intricate designs that are often impossible with conventional techniques.

One significant benefit is the reduction of material waste. Traditional molding methods often lead to excess scrap, increasing costs. Precision molding optimizes material usage, making it more efficient. It also enables faster production cycles. Shorter lead times can drive a better response to market demands. However, transitioning to precision molding can involve a steep learning curve. Companies must invest in specialized equipment and training.

There are challenges to consider as well. Not every part is suitable for precision molding. The initial setup can be costly and time-consuming. It's essential to weigh these factors against the benefits. Nonetheless, for many industries, the advantages can outweigh the drawbacks, leading to innovation and improved product quality.

Comparison of Precision Molding and Traditional Methods in Various Industries

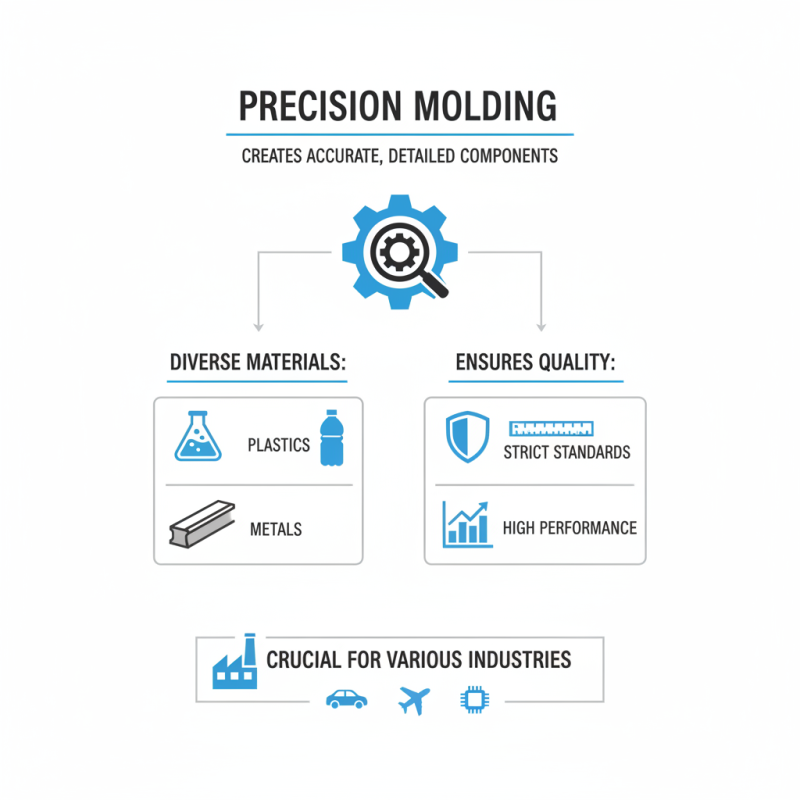

Common Applications of Precision Molding Across Industries

Precision molding is a vital process in various industries. It involves creating highly detailed and accurate components from diverse materials like plastics and metals. This technique is crucial for ensuring products meet stringent quality and performance standards. Many industries rely on precision molding for their manufacturing needs.

In the automotive sector, precision molding produces key parts like dashboard components and connectors. These parts must fit perfectly to ensure safety and functionality. Electronics also benefit from this process, with molded casings that protect sensitive components. However, inconsistencies in molding can lead to defects, affecting the entire product. That’s a critical area for improvement.

Medical device manufacturing uses precision molding for surgical instruments and implants. The exact measurements are essential for patient safety. Yet, achieving that precision can be challenging. Some companies struggle to perfect their molds, resulting in costly rework. These obstacles highlight the need for continuous innovation and detailed quality control in the industry.

Future Trends and Innovations in Precision Molding Technology

Precision molding is rapidly evolving. Advanced technologies are shaping the future of this industry. Innovations like smart sensors and automation are enhancing production efficiency. These tools allow for greater accuracy in the molding process. As a result, products are becoming more reliable and consistent.

Tip: Focus on integrating sustainable materials. This can lead to more eco-friendly products. Consider testing new materials in small batches to evaluate performance and suitability.

Artificial intelligence is also making waves. AI can predict defects during the molding process. This minimizes waste and reduces costs. The use of machine learning algorithms can optimize settings for various materials. Companies can fine-tune their approaches for better outcomes.

Tip: Stay updated on emerging AI technologies. Even incremental changes in workflow can yield significant benefits. Regularly review your processes for improvement opportunities. Limitations can lead to missed chances for innovation. Explore ways to adapt and grow in a competitive landscape.

Related Posts

-

What is Precision Molding and How Does it Impact Manufacturing Efficiency

-

The Future of Injection Mold Making Innovations Driving Efficiency and Cost Savings in Manufacturing

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023

-

Top 10 Benefits of Precision Injection Molding for Your Business Success

-

Top Molding Precision Techniques for Enhanced Product Quality?

-

5 Essential Tips to Maximize Efficiency in Injection Molding Processes