How to Master Contract Injection Molding for Your 2025 Production Needs

In today's rapidly evolving manufacturing landscape, the need for efficient and scalable production processes has never been more critical. One approach that has gained significant traction is contract injection molding, a method that allows businesses to leverage specialized expertise and advanced technology to meet their production demands. According to industry expert Dr. Emily Hartman, a leading consultant in plastic manufacturing, "Mastering contract injection molding is essential for companies aiming to streamline operations and enhance product quality in 2025 and beyond."

As organizations prepare for the challenges of modern production, understanding the intricacies of contract injection molding becomes a pivotal component of their strategic planning. This process not only reduces costs but also ensures a high-quality output, making it a preferred choice for many. In this guide, we will explore the essential steps to mastering contract injection molding, from selecting the right partner to optimizing manufacturing techniques, ensuring that your production needs are met with precision and efficiency as you head into the future.

Understanding the Basics of Contract Injection Molding Processes

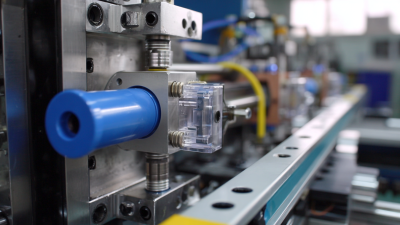

Contract injection molding is a specialized manufacturing process that involves creating plastic parts through the injection of molten polymer into a mold. Understanding the basics is crucial for companies looking to streamline their production needs for 2025. The process begins with designing the part and creating a mold that matches this design. A precision mold is critical, as it directly impacts the dimensional accuracy and quality of the final product.

Once the mold is ready, granulated plastic is heated until it melts and is then injected into the mold under high pressure. This allows the polymer to fill every intricate detail of the mold, ensuring that the final piece is a perfect representation of the original design. After cooling, the mold is opened, and the newly formed part is ejected. Throughout this process, factors such as temperature, injection speed, and cooling time must be meticulously controlled to yield optimal results. Mastering these fundamentals lays the groundwork for efficient and effective production in various industries, from automotive to consumer goods, ensuring businesses can meet their rising demands.

Key Considerations for Choosing a Reliable Injection Molding Partner

When it comes to mastering contract injection molding for production needs in 2025, selecting a reliable injection molding partner is crucial. The industry is projected to reach a market size of approximately $376.5 billion by 2025, highlighting the importance of choosing a partner capable of scaling operations effectively while maintaining quality. A reputable partner will offer not only advanced technology but also deep industry knowledge, ensuring they can adapt to evolving demands and trends within the sector.

Key considerations for this selection process include evaluating the partner's technical expertise and production capabilities. According to a report from the Plastics Industry Association, around 70% of successful projects stem from strong collaboration between manufacturers and their injection molding partners. This collaboration should encompass everything from design assistance to the implementation of efficient production processes. Furthermore, assessing their commitment to sustainability and innovation can provide insights into their long-term viability, especially as consumer preferences shift and regulations become more stringent. Selecting a partner that prioritizes these aspects can significantly impact the efficiency, cost-effectiveness, and environmental footprint of your injection molding operations moving forward.

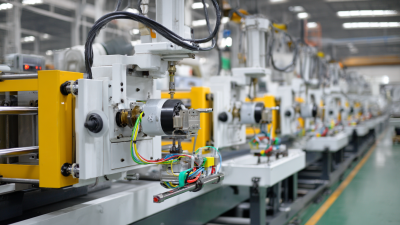

Essential Equipment and Technology for Efficient Production

To achieve efficient production in contract injection molding, it is essential to invest in the right equipment and technology. High-quality injection molding machines are at the heart of this process, as they determine the precision and consistency of the final products. Advanced servo-driven systems offer superior energy efficiency and faster cycle times, enhancing productivity while reducing operational costs. Additionally, integrating real-time monitoring systems can provide invaluable data, allowing for continuous optimization of the molding process and early detection of potential issues.

In conjunction with advanced machinery, utilizing state-of-the-art mold design software is critical for ensuring that molds are crafted to the highest standards of accuracy. Such software can simulate the injection process and identify potential flaws before production begins, saving time and resources. Furthermore, incorporating automated finishing equipment can streamline post-processing tasks, such as trimming and assembly, thereby reducing labor costs and increasing throughput. By focusing on these essential technologies, manufacturers can not only meet but exceed their production needs in the ever-evolving landscape of contract injection molding.

Quality Control and Testing Methods in Injection Molding

Quality control and testing methods are crucial in the injection molding industry, especially as production needs evolve heading into 2025. A recent report by the Plastics Industry Association highlighted that over 30% of manufacturers cite quality assurance as a top priority in their operations. Effective quality control involves various techniques, including optical inspection, dimensional checks, and mechanical testing, which help ensure that each molded part meets stringent specifications.

In addition, the implementation of advanced testing methods, such as melt flow index (MFI) testing and tensile testing, can provide critical insights into material performance and integrity. According to the American Society for Testing and Materials (ASTM), maintaining strict adherence to testing standards can reduce defects by up to 15%, which in turn can significantly decrease production costs and waste. As production demands rise, leveraging these quality control methodologies will be essential for manufacturers looking to meet customer expectations while optimizing their processes for efficiency and sustainability.

Future Trends in Contract Injection Molding for 2025 and Beyond

As we look toward 2025 and beyond, the landscape of contract injection molding is rapidly evolving. Companies are increasingly adopting advanced technologies like automation and artificial intelligence to enhance production efficiency and precision. These innovations not only streamline the manufacturing process but also significantly reduce waste, which is becoming a crucial factor in a world that prioritizes sustainability. By staying ahead of these trends, businesses can position themselves competitively while meeting rising demand for high-quality molded parts.

**Tips:** Embrace automation in your production facilities. Implementing automated systems can lead to faster turnaround times, improved consistency, and lower labor costs. Additionally, prioritize sustainable practices by sourcing eco-friendly materials and minimizing energy consumption during the molding process.

Another major trend taking shape is the customization of injection-molded products. With consumers increasingly seeking tailored solutions, manufacturers who leverage flexible production capabilities will stand out. By integrating modular designs and additive manufacturing techniques, companies can create bespoke products while maintaining efficiency in their operations.

**Tips:** Invest in training and development for your team to enhance their skills in managing flexible manufacturing systems. Additionally, utilize data analytics to understand customer preferences better, allowing you to refine your offerings and improve market responsiveness.

Related Posts

-

Exploring Market Trends and Innovations in Injection Molding Contract Manufacturing for 2024

-

Unlocking Efficiency: The Key Benefits of Contract Injection Molding for Manufacturing Success

-

Advantages of Injection Mold Manufacturing for Enhancing Production Efficiency and Reducing Costs

-

How to Maximize Efficiency in Precision Injection Molding Processes

-

Understanding the Benefits of US Injection Molding in Modern Manufacturing Practices

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023