How to Leverage Rapid Prototyping Injection Molding for Faster Product Development

In today's fast-paced market, the demand for efficient and innovative product development has never been greater. Companies are constantly seeking ways to reduce time-to-market while maintaining high quality and functionality in their products.

One of the most effective strategies for achieving this is through rapid prototyping injection molding. This advanced manufacturing technique allows businesses to quickly produce high-quality prototypes, enabling them to test and refine designs swiftly and economically.

By leveraging rapid prototyping injection molding, companies can not only accelerate their development cycles but also enhance collaboration among teams, reduce costs associated with traditional prototyping methods, and ultimately deliver superior products that meet consumer needs.

In this blog, we will explore the numerous benefits of this approach and how it can transform your product development processes, making it a vital tool for any organization looking to thrive in a competitive landscape.

Understanding Rapid Prototyping Injection Molding and Its Benefits

Rapid prototyping injection molding (RPIM) has revolutionized the way products are developed, offering significant advantages over traditional methods. By utilizing advanced software and manufacturing techniques, companies can create prototype molds quickly and efficiently. According to a report by the American Society for Quality, rapid prototyping can reduce product development time by up to 30%, allowing businesses to respond swiftly to market demands and remain competitive.

The benefits of RPIM extend beyond just speed. With reduced lead times, organizations can conduct thorough testing and iterations, ensuring product quality before full-scale production. A study from the Institute of Manufacturing shows that employing rapid prototyping can save up to 50% in costs associated with product design and development. This adaptability enables teams to innovate and deliver solutions faster, significantly enhancing overall productivity. As industries continue to embrace these techniques, the integration of RPIM into the product development life cycle becomes essential for maintaining a competitive edge.

Product Development Timeline with Rapid Prototyping Injection Molding

Key Differences Between Traditional and Rapid Prototyping Injection Molding

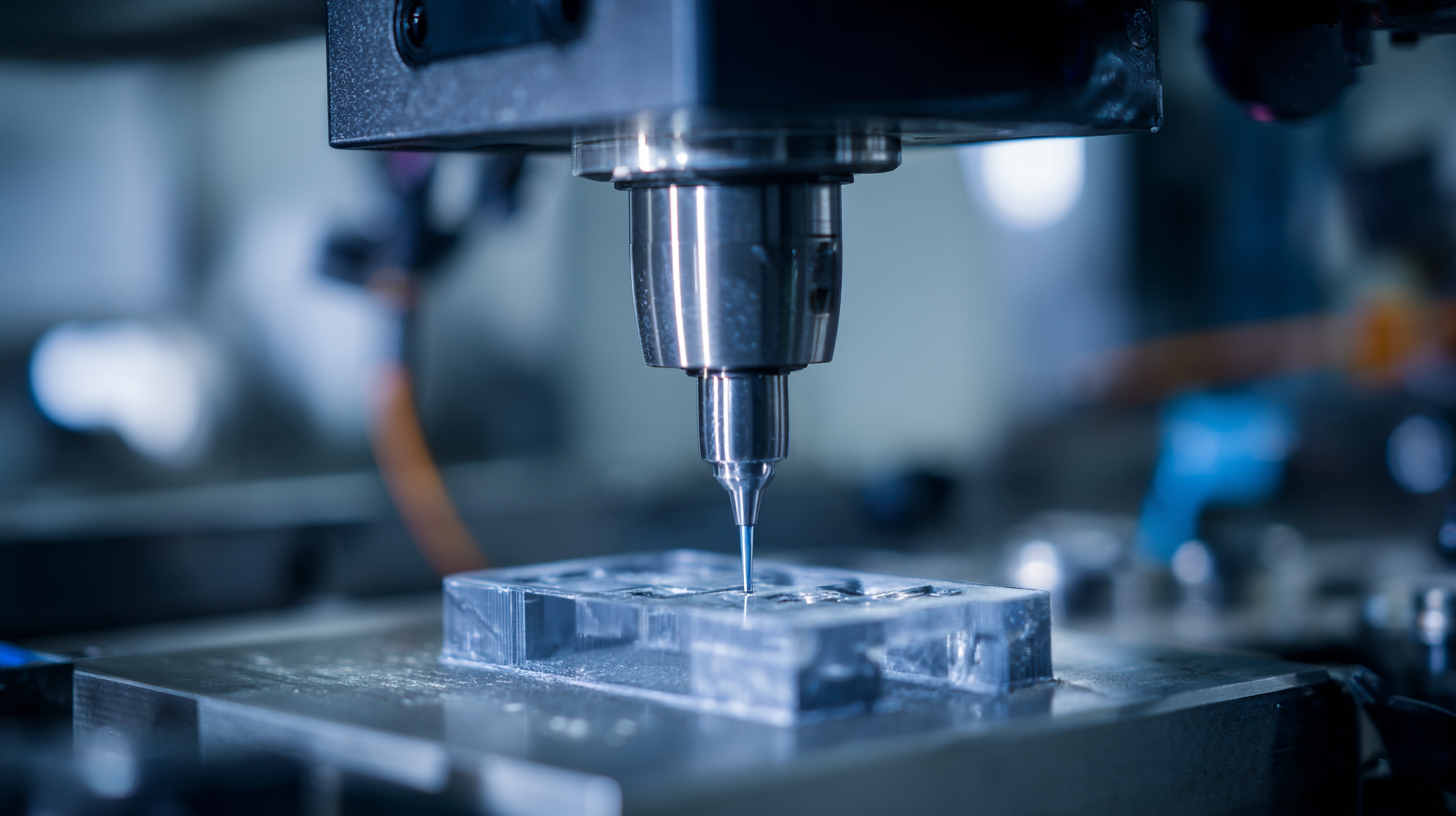

Traditional injection molding has long been the gold standard for producing high-quality plastic parts at scale. However, it is often a time-consuming process that involves creating and refining complex molds, which can take weeks or even months. This lengthy lead time can be a significant drawback for companies looking to innovate quickly. In contrast, rapid prototyping injection molding offers a more agile approach. This method employs advanced technologies such as 3D printing and CNC machining to create molds more efficiently, allowing products to transition from concept to production much faster.

One of the key differences lies in the materials used for the molds. Traditional injection molds are typically made from hard steel or aluminum, making them durable but costly and time-intensive to produce. Rapid prototyping, however, utilizes softer materials that can be machined quicker and with less expense, enabling companies to iterate designs without the burden of high initial costs. Additionally, rapid prototyping allows for design changes to be made on-the-fly, accommodating adjustments based on feedback much more swiftly. This flexibility not only expedites the development process but also fosters innovation, enabling teams to test multiple iterations without substantial investment or delays.

How to Leverage Rapid Prototyping Injection Molding for Faster Product Development

| Dimension | Traditional Injection Molding | Rapid Prototyping Injection Molding |

|---|---|---|

| Time to Market | 6-12 months | 2-6 weeks |

| Cost Per Part | $1 - $100 (depending on complexity) | $0.10 - $5 (for small runs) |

| Material Variety | Limited to production-grade materials | Wide range, including rapid prototyping materials |

| Mold Life | 100,000+ cycles | 1,000 - 10,000 cycles |

| Design Changes | Difficult and expensive | Easy and cost-effective |

| Ideal For | Mass production | Prototyping and small batch production |

Step-by-Step Guide to Implementing Rapid Prototyping in Product Development

Rapid prototyping injection molding has emerged as a game-changer in product development, significantly reducing lead times and costs. According to a report by Grand View Research, the global prototyping market is expected to reach USD 20.84 billion by 2025, driven by the increasing demand for product innovation across various industries. This process allows designers and manufacturers to create a working model of their product in days rather than weeks, offering a substantial competitive edge.

To effectively implement rapid prototyping in product development, it's essential to follow a structured approach. First, define the objectives and specifications of the prototype. Next, select appropriate materials, taking into account factors such as durability and cost-efficiency. A study from Wohlers Associates reveals that using advanced materials can save up to 60% in production time and reduce costs by 30%. Once the design has been finalized, utilize computer-aided design (CAD) software for precision before creating the mold. By integrating these steps, teams can achieve accelerated cycle times and improved product quality, while also fostering a culture of innovation within their organizations.

Common Challenges in Rapid Prototyping and How to Overcome Them

Rapid prototyping in injection molding presents significant advantages for product development, yet it is not without its challenges. One of the prevalent obstacles faced is the high initial investment cost. According to a report by Mordor Intelligence, the rapid prototyping market is expected to grow at a CAGR of 14.2% from 2021 to 2026, indicating increasing industry reliance on these techniques. However, businesses often struggle to justify the upfront expenditure associated with advanced prototyping technologies.

Another challenge is the material selection process. Different prototypes require distinct materials to accurately represent the final product’s performance. Research from Gartner indicates that 70% of product failures stem from inadequate material choices during the prototyping phase. To overcome this, companies can utilize predictive analytics tools to assess material performance and suitability effectively, thus streamlining the decision-making process. By addressing these common challenges with strategic solutions, organizations can harness the full potential of rapid prototyping in injection molding, leading to faster and more successful product development cycles.

Real-World Examples of Successful Rapid Prototyping Injection Molding Applications

Rapid prototyping injection molding has emerged as a game-changer in the product development landscape, enabling companies to transform concepts into tangible products at an unprecedented pace. For instance, according to a report by Allied Market Research, the global injection molding market is projected to reach $341.49 billion by 2025, with rapid prototyping playing a pivotal role in this expansion. This approach allows for quick iterations and modifications, significantly reducing the time-to-market for new products.

Real-world applications of rapid prototyping injection molding abound across various industries. In the automotive sector, companies like Ford and General Motors have utilized this technology to rapidly create and test prototypes, enabling them to refine designs based on feedback before committing to traditional manufacturing processes. A specific example includes Ford’s use of 3D printing combined with injection molding to develop parts for the Ford F-150, which saved them an estimated 30% in both time and cost compared to conventional methods. Similarly, in the consumer electronics industry, firms are adopting rapid prototyping to develop innovative devices, shortening their development cycles and enhancing competitive advantage. This evolution showcases the critical role that rapid prototyping injection molding plays in fostering innovation and efficiency in product design and development.

Related Posts

-

Tailored Solutions for Rapid Prototyping Injection Molding: Driving Efficiency with Accurate Data Insights

-

Maximizing Efficiency: Key Advantages of Injection Molding in Modern Manufacturing

-

Innovative Injection Molding Applications That Redefine Manufacturing Standards

-

Innovative Solutions for Rapid Injection Molding Efficiency Optimization

-

How to Optimize Insert Injection Molding for Increased Efficiency

-

Understanding the Role of Precision Injection in Modern Manufacturing