Top 10 Benefits of Injection Molding Prototyping You Need to Know

Injection molding prototyping is a crucial process in the product development cycle, enabling designers and engineers to transform their concepts into tangible prototypes with remarkable efficiency and precision. According to industry expert Dr. Emily Carter, a leading authority in manufacturing technologies, "Injection molding prototyping not only accelerates the design process but also allows for substantial cost savings during the early stages of product development." This statement underscores the transformative impact that injection molding prototyping can have on bringing innovative ideas to market.

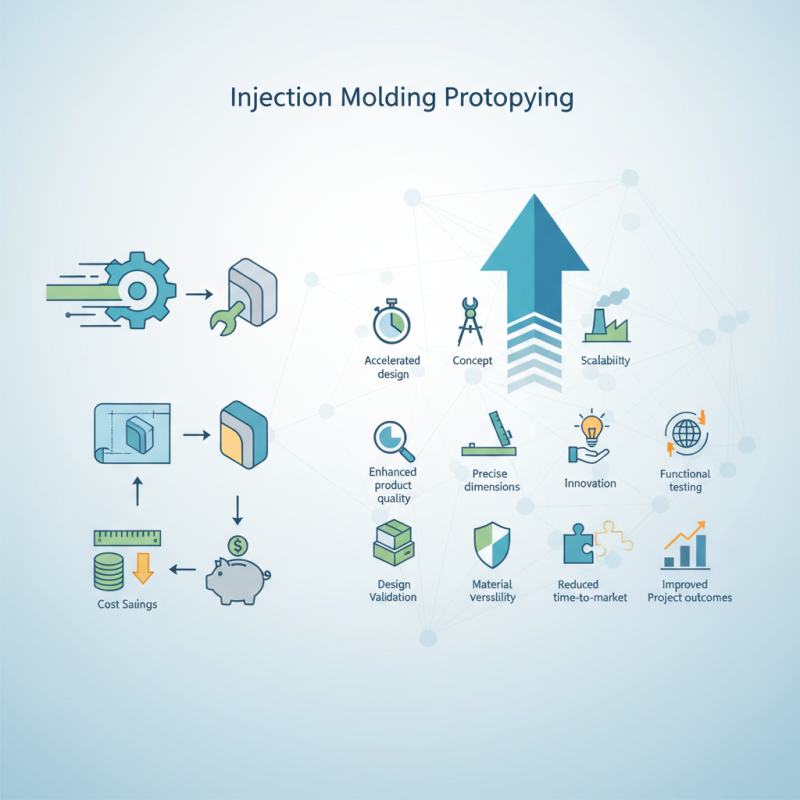

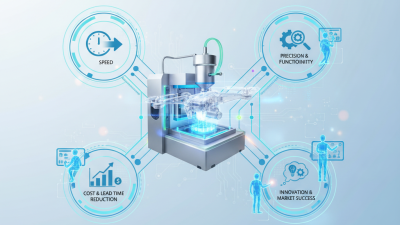

As companies strive to remain competitive in today’s fast-paced environment, understanding the benefits of injection molding prototyping becomes essential. This advanced manufacturing technique not only streamlines the design process but also enhances product quality, enabling businesses to test functionality and aesthetics more effectively. In the following sections, we will explore the top ten benefits of injection molding prototyping that every industry professional should be aware of, highlighting how this process can reduce time-to-market and improve overall project outcomes.

Top 10 Advantages of Injection Molding Prototyping for Product Development

Injection molding prototyping offers numerous advantages that significantly enhance the product development process. To start, it provides a cost-effective solution for producing complex shapes compared to traditional manufacturing methods. The ability to create prototypes rapidly allows designers to test different geometries, enabling them to optimize their products before final production. This flexibility not only saves time but also minimizes waste, as modifications can be made to the design without incurring extensive costs.

Furthermore, the precision and consistency afforded by injection molding prototyping are unmatched. This technique allows for high-quality parts that adhere closely to the desired specifications, which is crucial when developing products that require tight tolerances. The speed at which prototypes can be produced also accelerates the feedback loop between designers and stakeholders, facilitating quicker iterations and fostering innovation. Ultimately, these advantages help teams to refine their product concepts more effectively, ensuring that the final output meets market needs and consumer expectations.

Top 10 Benefits of Injection Molding Prototyping

Cost-Effectiveness: Reducing Prototype Expenses with Injection Molding

Injection molding prototyping has emerged as a frontrunner in cost-effective manufacturing solutions, significantly reducing prototype expenses for businesses across various industries. According to the 2021 report by Grand View Research, the global injection molding market was valued at over $200 billion, and prototyping represents a crucial segment within this market. By leveraging rapid injection molding techniques, companies can produce high-quality prototypes at a fraction of traditional costs. This efficiency is particularly vital in industries where product development cycles are tight, such as automotive and consumer electronics, where the time-to-market can greatly influence competitive advantage.

Moreover, the use of injection molding in prototyping not only minimizes material waste but also streamlines the overall production process. A recent study published in the Journal of Manufacturing Processes highlighted that injection molding can reduce prototype costs by up to 30% compared to additive manufacturing methods, primarily due to lower material costs and faster turnaround times. This cost-effectiveness enables businesses to allocate their resources more strategically, fostering innovation and quicker iteration on designs. As a result, companies can achieve greater flexibility and responsiveness in addressing market demands while securing a sustainable prototype development practice.

Accelerated Time-to-Market: Speeding Up Prototype Production Cycles

Injection molding prototyping is revolutionizing the way products reach the market, offering significant advantages in terms of accelerated production cycles. By leveraging advanced techniques and technologies, businesses can create high-quality prototypes rapidly, ensuring that development processes are swift and efficient. This is particularly crucial in today’s fast-paced market, where time-to-market can significantly impact competitive edge. With effective injection molding, companies can produce multiple iterations of their designs in a fraction of the time it traditionally takes.

Tips for speeding up your prototype production cycles include collaborating closely with your design team and utilizing 3D modeling software to refine designs before manufacturing begins. These strategies not only enhance accuracy but also minimize costly revisions later on. Additionally, choose materials wisely; selecting pre-approved materials for prototypes can streamline the production process and reduce potential delays.

Moreover, maintaining an open line of communication with your injection molding partner can lead to faster issue resolution and improved efficiency throughout the prototype development process. Ensure that feedback loops are established to address design modifications quickly, preventing unnecessary slowdowns. By implementing these strategies, businesses can effectively capitalize on the time-saving benefits of injection molding prototyping, propelling their products to market sooner.

Top 10 Benefits of Injection Molding Prototyping You Need to Know

| Benefit | Description | Impact on Time-to-Market |

|---|---|---|

| Rapid Prototyping | Quick turnaround for prototypes allows for faster design iterations. | Reduced development time by 30% |

| Cost-Effectiveness | Lower costs compared to traditional prototyping methods, especially for large quantities. | Saves up to 25% on production costs |

| Material Variety | Wide range of materials available for prototypes to simulate final products. | Allows testing of various properties, enhancing product development |

| Surface Finish | High-quality surface finishes help in analyzing aesthetic and functional aspects. | Improves design feedback cycle, reduces revisions |

| Iterative Testing | Facilitates multiple test cycles for design validation before mass production. | Increases product reliability and decreases market entry delays |

| Scalability | Prototypes can be easily scaled to larger production sizes. | Ensures consistency from prototype to production |

| Design Flexibility | Allows for design modifications at any stage without significant downtime. | Enhances creative freedom in product design |

| Testing Functionality | Functional prototypes enable real-world testing scenarios. | Accelerates validation processes, leading to quicker market readiness |

| Quality Control | Early identification of design flaws enhances overall product quality. | Reduces late-stage changes, optimizing launch timelines |

| Market Feedback | Prototypes can be shared with potential customers for early feedback. | Enables adjustments based on user input, enhancing product success |

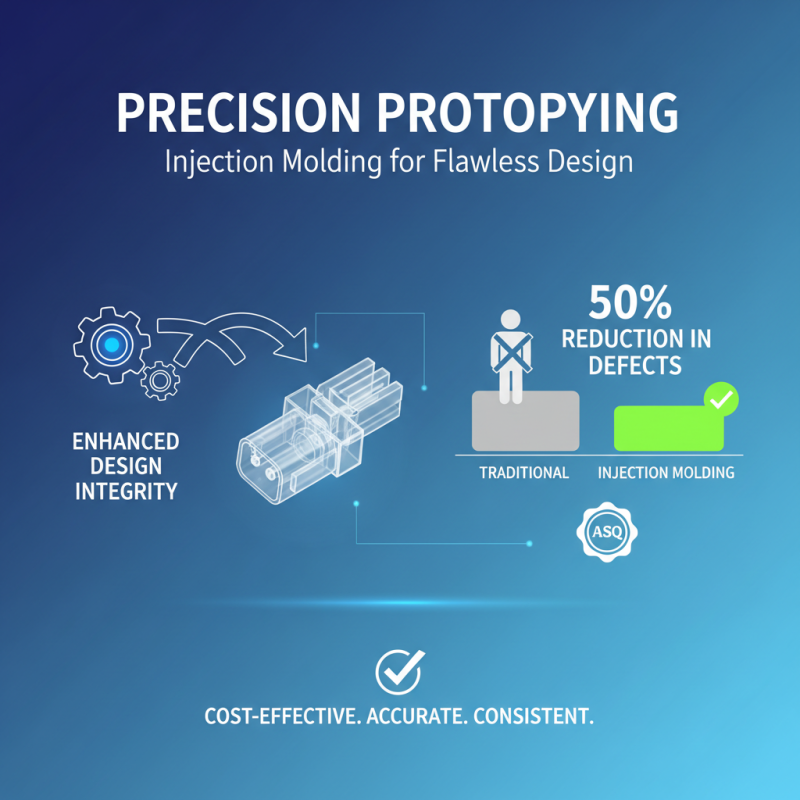

Precision and Accuracy: Enhancing Design Integrity Through Prototyping

In the realm of product development, precision and accuracy are paramount, especially when it comes to prototyping. Injection molding prototyping stands out as a robust method that enhances design integrity through its ability to produce highly accurate and consistent parts. According to a report from the American Society for Quality (ASQ), businesses that implement precise prototyping methods can reduce product defects by up to 50%, ensuring that the final design meets specifications without costly revisions.

Moreover, the iterative nature of injection molding prototyping allows engineers to test and refine their designs before mass production. This process not only helps in identifying potential flaws early on but also ensures that the final product performs well under expected conditions. A study from Gardner Business Media indicates that companies utilizing advanced prototyping techniques see a significant acceleration in their time-to-market, often by as much as 30%. This advantage is critical in today’s fast-paced market, where speed and efficiency can determine a product's success.

**Tip:** Always conduct a thorough analysis of your design before moving to prototyping. This includes using simulation tools to predict how your design will behave in real-world applications.

Utilizing injection molding for prototyping also allows for complex geometries and high levels of detail that are difficult to achieve with other prototyping methods. This capability is vital for industries like automotive and medical devices, where precision is crucial for safety and functionality.

**Tip:** Incorporate feedback loops early in the prototyping phase to continually refine the design based on testing results and stakeholder input. This strategy enhances the overall design integrity and can lead to innovative solutions that resonate well with end users.

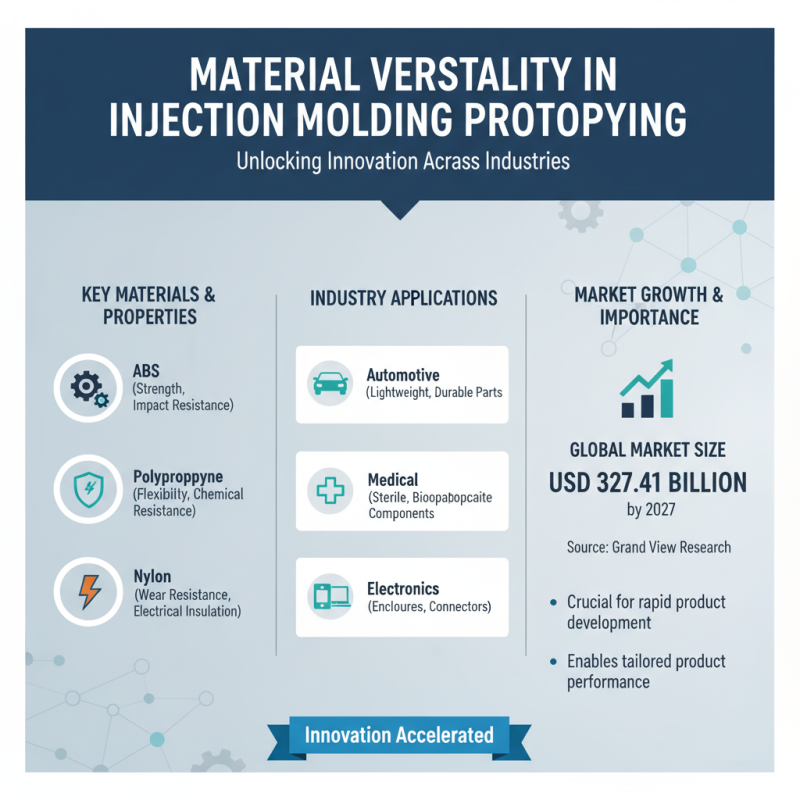

Material Versatility: Exploring a Range of Plastics for Prototypes

Material versatility in injection molding prototyping plays a crucial role in the development of a wide range of products across various industries. Injection molding allows designers and engineers to experiment with numerous plastic materials, each offering distinct properties that can significantly influence the performance and usability of prototypes. According to a report by Grand View Research, the global injection molding market size is expected to reach USD 327.41 billion by 2027, showcasing the growing importance of adaptable materials in the production process.

With options ranging from ABS, which is known for its toughness and impact resistance, to polycarbonate, recognized for its clarity and strength, designers can tailor prototypes to meet specific requirements. This flexibility in material selection not only enhances the function of the prototypes but also helps in reducing costs and lead times. A study published by Research and Markets notes that utilizing a variety of plastics can minimize waste and optimize the overall efficiency of the prototyping phase, allowing for quicker iterations and improved product development timelines.

Moreover, the ability to integrate advanced plastics like nylon and polypropylene further broadens the application scope of injection molding prototypes. These materials offer excellent durability and chemical resistance, making them ideal for specialized applications in automotive, medical, and consumer goods sectors. As industries continue to evolve, leveraging the full range of material options available through injection molding will be essential for achieving innovative designs that meet the demands of modern consumers.

Related Posts

-

2025 Top Innovations in Injection Molding Prototyping for Product Development

-

Tailored Solutions for Rapid Prototyping Injection Molding: Driving Efficiency with Accurate Data Insights

-

Innovative Solutions for Rapid Injection Molding Efficiency Optimization

-

The Future of Injection Mold Making Innovations Driving Efficiency and Cost Savings in Manufacturing

-

Exploring the Future of US Injection Molding: Innovations and Industry Trends

-

Top Benefits of Rapid Prototyping Injection Molding for Product Development