2025 Top Trends in Injection Molding Prototyping You Need to Know

In recent years, the landscape of injection molding prototyping has rapidly evolved, driven by technological advancements and increased demand for faster product development cycles. Experts in the field are observing significant trends that could reshape how businesses approach prototyping in 2025 and beyond. According to Dr. Emily Chen, a leading authority in injection molding technology, "The future of injection molding prototyping lies in our ability to harness innovative materials and processes that enhance efficiency and precision."

As industries strive for more sustainable practices and reduced time-to-market, the importance of staying informed about the emerging trends in injection molding prototyping cannot be overstated. Companies must adapt to new methodologies, such as integrating digital manufacturing technologies and leveraging advanced materials to meet evolving customer expectations. The upcoming years promise exciting developments that will influence not just the prototyping processes but also the overall manufacturing landscape. Understanding these trends will be crucial for businesses aiming to maintain a competitive edge in today's fast-paced environment.

Emerging Technologies in Injection Molding Prototyping for 2025

As we look ahead to 2025, the field of injection molding prototyping is witnessing a wave of emerging technologies that are set to transform the industry. The integration of advanced materials, such as bioplastics and high-performance composites, is reshaping how prototypes are designed and produced. These innovative materials not only enhance product performance but also improve sustainability in manufacturing processes. This shift towards greener options is appealing to companies aiming to reduce their environmental footprint while delivering high-quality prototypes.

Tips: When exploring these new materials for your injection molding projects, consider conducting thorough material compatibility tests. This will ensure that your prototypes perform under real-world conditions and meet expected tolerances.

Additionally, the rise of automation and AI in injection molding prototyping allows for greater precision and efficiency. Automated systems can optimize production schedules, reduce cycle times, and minimize human error, leading to higher quality outputs. The implementation of AI-driven design tools also helps engineers to swiftly iterate on designs, saving time and resources in the prototyping phase.

Tips: Stay updated on the latest software tools that leverage AI in design. Investing in training for your team can significantly enhance your prototyping capabilities and keep you competitive in this rapidly evolving landscape.

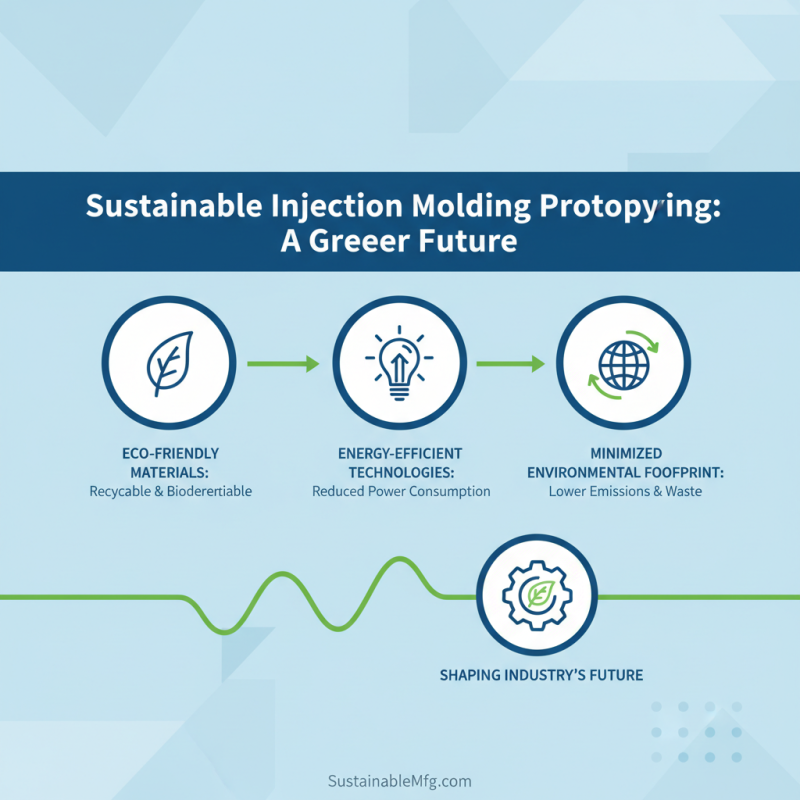

Sustainability Practices in Injection Molding Processes

Sustainability has become a paramount concern in the realm of injection molding prototyping, shaping not only the industry’s practices but also its future. As companies seek to minimize their environmental footprint, they are increasingly integrating sustainable practices into their injection molding processes. This shift includes the adoption of eco-friendly materials that are recyclable or biodegradable, which reduce the reliance on traditional plastics. Furthermore, manufacturers are exploring energy-efficient technologies that lessen power consumption during the molding process, leading to a significant decrease in greenhouse gas emissions.

Moreover, waste reduction strategies are being implemented throughout the injection molding lifecycle. This includes optimizing production schedules to minimize scrap and rework, as well as employing closed-loop systems that allow for the reuse of materials. By investing in advanced molding techniques, such as precision molding and additive manufacturing, businesses can achieve a more sustainable approach while maintaining quality and efficiency. As these practices gain momentum, they not only enhance a company's reputation but also pave the way for innovations that could revolutionize the injection molding industry, creating a more sustainable and responsible manufacturing landscape.

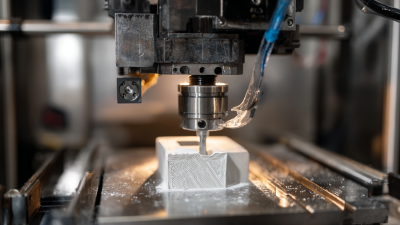

Advancements in Materials Used for Prototyping in 2025

As we approach 2025, advancements in materials for injection molding prototyping are set to revolutionize the manufacturing landscape. One of the most significant trends is the development of bio-based and biodegradable materials. These environmentally friendly options not only reduce the carbon footprint associated with traditional plastics but also cater to the increasing consumer demand for sustainable products. Innovations in plant-based polymers and composites are becoming more prevalent, allowing prototypes to be produced that are not only functional but also aligned with eco-conscious initiatives.

Additionally, the incorporation of advanced additives and fillers in prototyping materials is enhancing the performance characteristics of molded parts. For instance, materials infused with nanomaterials provide improved strength, thermal stability, and resistance to wear. This leads to prototypes that better mimic the final production components, enabling more accurate testing and validation during the product development phase. The integration of these cutting-edge materials into injection molding processes ensures that manufacturers can produce prototypes that meet rigorous industry standards while exploring new design possibilities.

2025 Trends in Injection Molding Prototyping

Integration of AI and Automation in Injection Molding Techniques

The integration of artificial intelligence (AI) and automation in injection molding techniques represents a significant evolutionary shift in the manufacturing landscape. As per a recent industry report by Grand View Research, the global injection molding market is poised to reach $340 billion by 2025, with the adoption of AI and automation playing a crucial role in this growth. By leveraging advanced algorithms, manufacturers can optimize their processes, reduce waste, and enhance product quality. AI technologies can analyze vast amounts of data in real time, allowing for predictive maintenance and minimizing downtime, which is particularly valuable in high-production environments.

Furthermore, automation in injection molding enhances operational efficiency and precision. The implementation of robotic systems and intelligent machines can streamline workflows, reduce human error, and drastically cut down cycle times. According to a report by McKinsey & Company, automation can increase productivity rates by up to 30% in the manufacturing sector. As companies increasingly embrace smart factories characterized by interconnected equipment, the injection molding processes are evolving to become more responsive and adaptable, ensuring that manufacturers remain competitive in an ever-changing market. The confluence of AI and automation not only enhances productivity but also drives innovation in design and material usage, paving the way for a new era of prototyping and production efficiency.

Market Trends Influencing Injection Molding Prototyping in 2025

As we approach 2025, the landscape of injection molding prototyping is poised for significant evolution, influenced by various market trends. One notable trend is the increasing demand for customization and rapid prototyping. Companies are leaning towards injection molding methods that can accommodate smaller production runs and more diverse geometries, enabling the creation of tailored products for niche markets. This shift is largely driven by consumer preferences for unique and personalized items, prompting manufacturers to adopt more

flexible prototyping techniques.

Another pivotal trend is the integration of advanced technologies within the injection molding process. Automation and artificial intelligence are being harnessed to enhance efficiency, reduce cycle times, and minimize defects. The rise of smart manufacturing is facilitating real-time data analysis, allowing manufacturers to optimize their processes and improve overall product quality. Additionally, sustainability concerns are pushing companies to innovate in material selection, employing biodegradable and recyclable materials which align with global efforts towards environmental responsibility. This dual focus on technological advancement and sustainability will undoubtedly shape the future of injection molding prototyping as we move deeper into 2025.

Related Posts

-

5 Digital Tips for Effective Injection Molding Prototyping Success

-

How to Effectively Utilize Injection Molding Prototyping for Your Product Development

-

Tailored Solutions for Rapid Prototyping Injection Molding: Driving Efficiency with Accurate Data Insights

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency

-

Innovative Solutions for Rapid Injection Molding Efficiency Optimization

-

Why Injection Molding Prototyping is Essential for Product Development Success